1.What are Cutting Conditions?

To perform machining, a machine tool needs to have specified numerical values for cutting speed, rotation speed, feed rate, and depth of cut, which are referred to as cutting conditions (or machining conditions).

Cutting conditions vary depending on the material of the workpiece and the cutting tool, as well as the desired shape to be cut, and must be adjusted each time these factors change. If the cutting conditions are not appropriate, various disadvantages can arise, such as poor machining accuracy, longer processing times, and tools chipping or wearing out prematurely.

Maintaining a balance among the various machining factors while optimizing all of them can be quite challenging. For example, prioritizing machining speed can lead to increased load and vibration on the workpiece and cutting tools, which can in turn affect precision and the lifespan of the tools. Deciding what to prioritize and finding the right balance is a case-by-case matter, and there is no single correct value.

2.Contents of Cutting Conditions and How to Calculate Them

The following explanation is based on the use of lathes and milling machines.

Cutting Speed

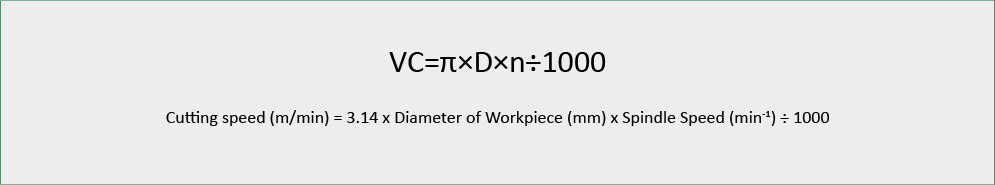

Cutting speed represents the speed of cut per minute.

In the case of a lathe, rotation is also involved, and it is referred to as the peripheral speed.

- -The higher the cutting speed, the better the machining accuracy, the shorter the machining time, and the greater the load on the cutting tool.

- -The slower the cutting speed, the lower the machining accuracy, the longer the machining time, and the lower the load on the cutting tool.

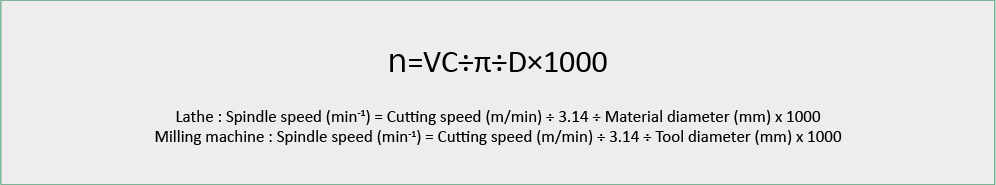

Spindle Speed (RPM)

In a lathe, it represents the number of revolutions the spindle makes per minute, while in a milling machine, it indicates the number of revolutions the cutting tool makes per minute.

The spindle speed and cutting conditions are proportional.

- -The higher the spindle speed, the faster the cutting speed.

- -The lower the spindle speed, the slower the cutting speed.

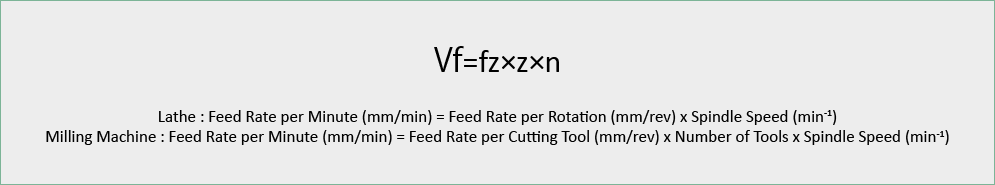

Feed Rate

Feed rate refers to the amount or speed of cutting tool movement per minute.

- -The larger the feed rate, the lower the machining accuracy, the shorter the machining time, and the greater the load on the cutting tool.

- -The smaller the feed rate, the better the machining accuracy, the longer the machining time, and the smaller the load on the cutting tool.

Depth of Cut

The depth of cut is the depth to which the cutting tool cuts into the workpiece.

- -The larger the depth of the cut, the lower the machining accuracy, the shorter the machining time, and the greater the load on the cutting tool.

- -The smaller the depth of the cut, the better the machining accuracy, the longer the machining time, and the smaller the load on the cutting tool.

If the depth of cut is excessive, it can cause vibration due to deflection (chatter). Conversely, if the depth of cut is insufficient, it can lead to surface sliding phenomena (slip phenomenon, rubbing phenomenon).

3.Application of Cutting Conditions

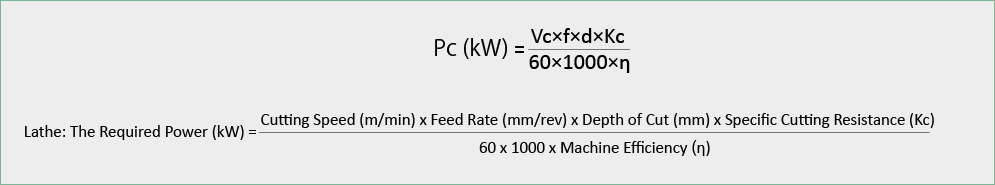

Required Motor Power

This is the result of combining the above cutting conditions with the cutting resistance to represent the actual power required by the motor.

If the required power exceeds the motor specifications, it is necessary to adjust the cutting conditions.

What is Specific Cutting Resistance?

When a workpiece pushes back against the cutting tool during cutting, it’s called cutting resistance. The ratio of cutting resistance to the cutting cross-sectional area is called specific cutting resistance. It varies depending on the material of the workpiece, and approximate values are as follows:

- Aluminium : 800MPa

- Copper : 2500~3000MPa

- Cast Iron : 1500MPa

What is Machine Efficiency?

The efficiency of the power generated by the motor that is utilized. Roughly estimated values range from 0.75 to 0.85.

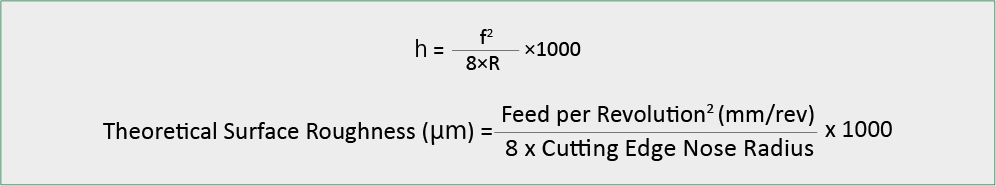

Theoretical Surface Roughness

It represents the theoretical surface roughness of the machined surface that can be obtained from cutting conditions.

In actual machining, further adjustments are required to account for the influence of material properties. Rough estimates suggest that for steel, the influence is 1.5 to 3 times, while for cast iron, it ranges from 3 to 5 times. Additionally, the cutting edge nose radius varies depending on the selected cutting tool.

If the theoretical surface roughness exceeds the specified tolerance for surface finish, adjustments such as altering the feed rate or switching to cutting tools with larger cutting edge nose radius may be necessary.

4.How to Determine Cutting Conditions

First, the recommended values from the cutting tool manufacturer.

Since cutting tool has a large influence, each cutting tool manufacturer lists recommended values in their catalogs. Various materials are available, but those with high hardness and heat resistance can perform high-speed cutting, while those with high toughness are durable and can be used for long machining time.

Considering the machine condition and its effect on accuracy, the actual value is often set lower than the recommended value.

What is Built-Up Edge?

This is a phenomenon where fine chips become part of the cutting edge, causing adverse effects on machining accuracy. It is more likely to occur with materials that have high affinity with iron.

Use System and Software

Many CNC lathes, milling machines, and multitasking machines have built-in cutting conditions tables as internal data and are equipped with systems and software that automatically set appropriate values when materials and types of machining are selected. Additionally, some manufacturers offer apps that can be used on smartphones or tablets for this purpose.

However, due to the wide range of factors such as material, shape, and required accuracy, it can be challenging to completely rely on automated settings for all machining tasks.

Experience and Familiarity Play Valuable Roles

When cutting a new workpiece, if you have machined a similar material and shape, you can make an adjustment based on previous experience.

Consider Priorities and Balance

In addition to the above decision-making of cutting conditions, further adjustments are made to determine the optimal priority and balance, such as prioritizing machining accuracy or slightly increasing the machining speed.

Check the Progress During Machining.

- Are there not any abnormal noises or fumes being emitted?

- Are the shape and color of the chips appropriate?

- Is the load value not exceeding 100%

What is Load Value?

The load is calculated based on the current value flowing through the motor. The load value can be used to adjust machining conditions while machining.

On Nakamura-Tome machines with NT Smart X, you can check the load status of each motor as shown in the figure below.

Regarding the shape and color of the chips, they are summarized in this article here.

When metal is cut using a lathe or milling machine, chips are generated in various forms such as spirals, ribbons and shavings. It’s said that you can tell a lot by looking at the color, shape, length, etc., of the chips

Click on Image to read the article

Chips in Machining: A Mine of Information!

5.Summary

Due to the wide variety of cutting materials, tool materials, and tool shapes, there is no definitive answer regarding cutting conditions. This often leads to confusion and uncertainty, especially for beginners. First, use the recommended values or those set automatically by the system. Verify the accuracy of the machined workpieces, ensure that the machining time is not excessive, evaluate whether the load on the cutting tools is excessive, and make adjustments as necessary. As you gain experience, you will be able to determine cutting conditions smoothly.

By consistently performing the best target cutting process from all perspectives, you can achieve high quality machining and reduce man-hours.

[Advertorial] Introduction to “Oscillation Cutting”